INSERTING

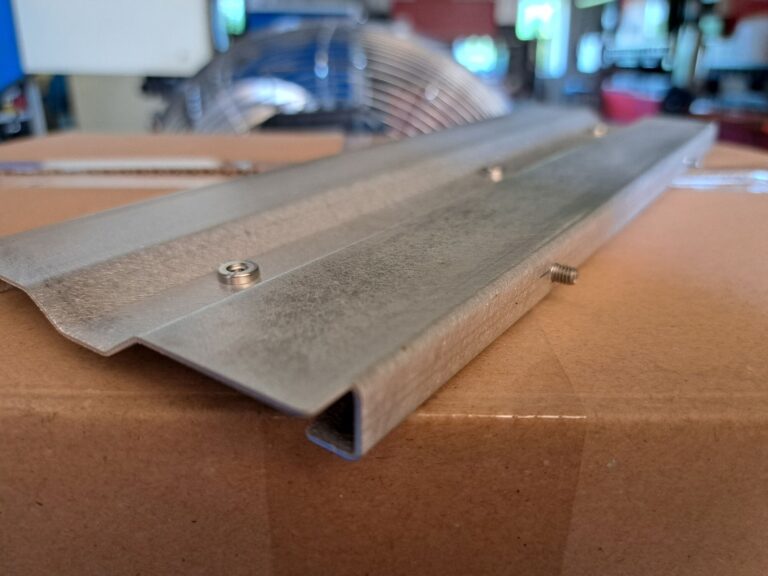

PRECISE INSERT MOUNTING

Inserting is an advanced technique for mounting inserts, ensuring durable and precise connections. If you need professional inserting services, explore our offer. We guarantee high quality and precision.

advantages of Inserting

-

Durability

Inserting provides exceptionally strong and durable connections that can withstand significant mechanical loads.

-

Precision

The inserting process ensures precise placement of inserts, which is critical in applications requiring high accuracy.

-

Versatility

This technique can be used with various materials and types of inserts, allowing for broad applications across industries.

-

Efficiency

Inserting is a fast and efficient process, which results in lower production costs and shorter lead times.

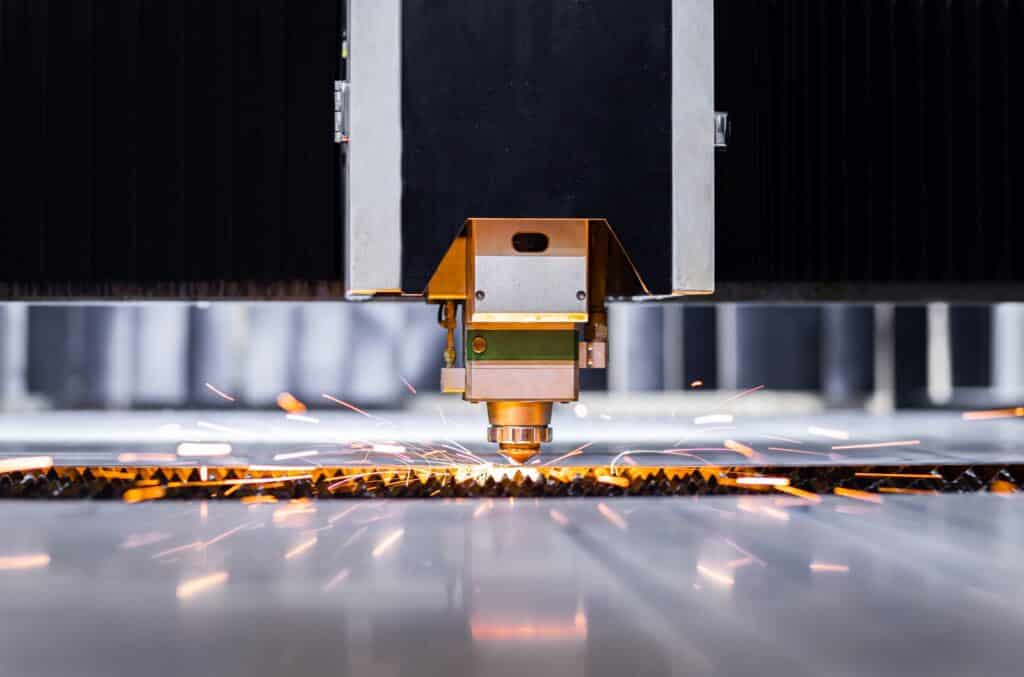

APPLICATION OF Inserting

-

E-mobility

Mounting reinforcing inserts in components for traction batteries used in public transport, as well as elements for electric vehicle chargers.

-

Automotive Industry

Mounting inserts in plastic, aluminum, and composite parts.

-

Electronics

Inserting threaded inserts into enclosures and electronic components.

-

Energy Storage

Inserting inserts into metal structures.

Inserting PROCESS

-

STAGE 1

Material Preparation

Cleaning and preparing holes for the insertion of inserts.

-

STAGE 2

INSERTING

Inserting and securing the inserts using specialized tools, ensuring precise and durable connections.

-

STAGE 3

Quality Control

Checking the correctness of the assembly and the strength of the connections to ensure their durability and functionality.