Quality Control

GUARANTEE OF HIGH PRODUCT QUALITY

Quality control is a crucial stage in the production process that ensures the highest standards and requirements are met. If you need professional quality control services, explore our offer. We guarantee accuracy and reliability.

advantages of Quality Control

-

Accuracy

Quality control enables the precise detection and elimination of defects, ensuring the highest product quality.

-

Compliance with Standards

Regular quality checks help maintain product compliance with applicable standards and regulations.

-

Customer Satisfaction

Ensuring high-quality products leads to greater customer satisfaction and helps build a positive company image.

-

Production Efficiency

Early detection of defects allows for quick removal, minimizing losses and increasing production efficiency.

APPLICATION OF Quality Control

-

E-mobility

Quality inspection of advanced constructions and components for traction batteries in public transport and elements for electric vehicle chargers.

-

Automotive Industry

Quality control of automotive parts, engine components, and drive systems.

-

Electronics Industry

Testing of electronic components, printed circuit boards, RTV devices, and household appliances.

-

Energy Storage

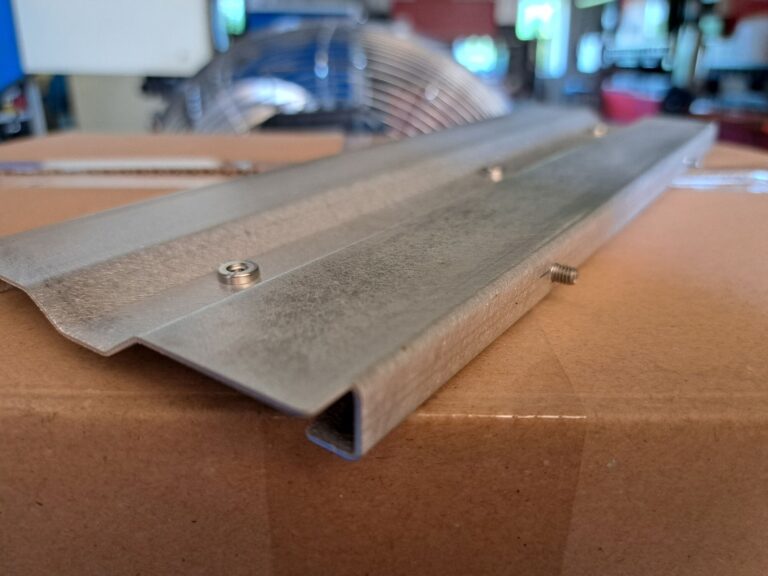

Quality control of complex metal structures, which pose challenges related to execution accuracy and stringent quality standards.

Quality Control PROCESS

-

STAGE 1

Planning of Control

Preparation and cleaning of elements for inspection.

-

STAGE 2

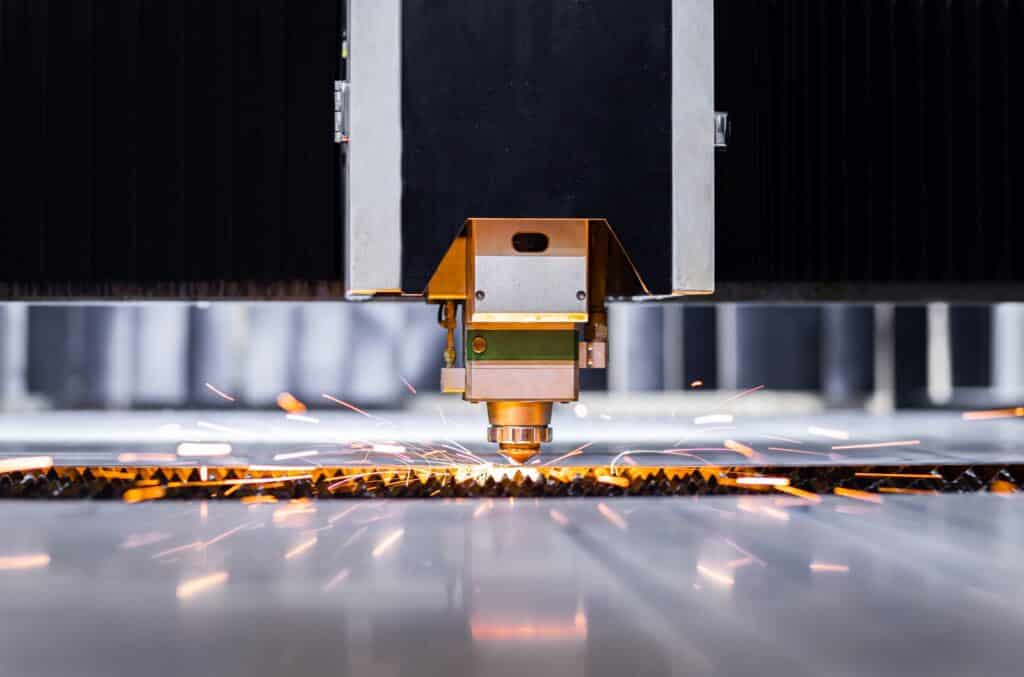

Conducting Tests and Inspections

Using appropriate methods to test and inspect based on material and technical requirements.

-

STAGE 3

Result Analysis

Verifying the strength and quality of connections to ensure durability and safety.

-

STAGE 4

Reporting

Documenting the results of quality control and preparing reports that inform the quality status of the products.